About Us

Who we are and how the intertooth came into being

The Beginning

As a network engineer, you are always putting new devices into operation, be it switches, routers or appliances. Most of these devices require an initial configuration so that they can be connected to the existing network and integrated correctly. For this purpose, the so-called console port is still often used today, which provides an RS232 interface to access the command line interface of the devices. This is usually in the form of a D-SUB, RJ45 or USB port.

Since today's notebooks no longer have an RS232 interface, a converter is needed which enables the connection to the console port. There are countless such converters on the market, mostly in the form of a cable with the required connectors (e.g. D-SUB for the console port of the network device and USB for the connection to the notebook). In order to use these converters, a corresponding driver is required, which must be installed. Handling these converter cables is cumbersome - most cables are rather short and the drivers are often unstable or not available for all platforms. This repeatedly led to situations where we were kneeling on the floor next to a rack somewhere in a data center because the cable was too short to sit down at a table. Once the connection was established, it was not uncommon for a blue screen to follow, triggered by the converter's driver.

The problem was recognized, now a solution had to be found.

The First Build

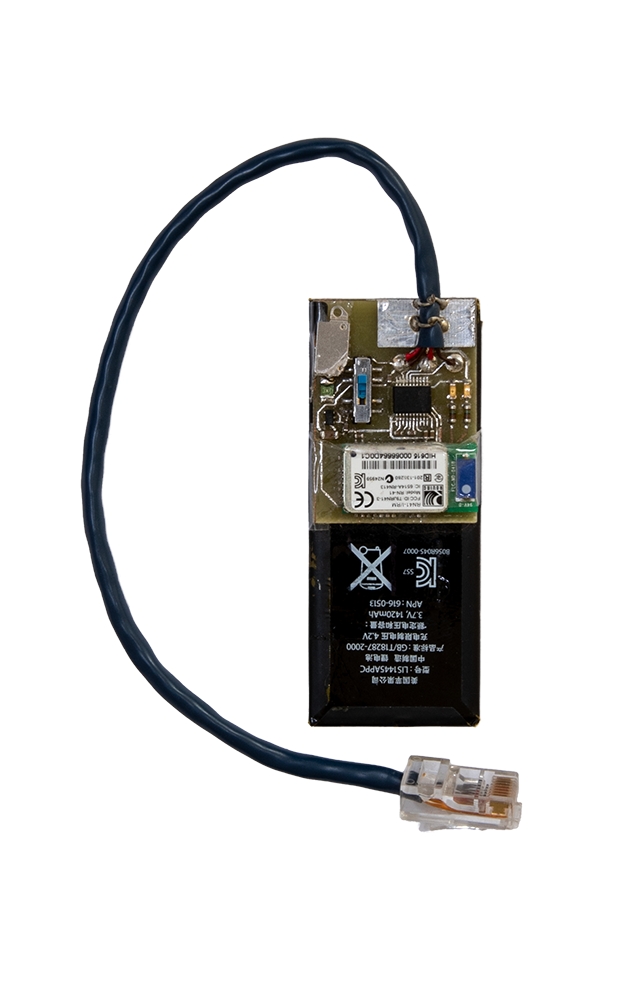

Bojan, a trained electronics engineer, didn't waste much time and decided to develop his own solution that would allow wireless access to a console port. Although there were a few converters on the market that enabled a connection via Bluetooth, they did not have an integrated power supply, which again made their use unnecessarily complicated. Bojan therefore developed a solution based on a Bluetooth module and the battery of an old cell phone. At that time, Bojan and Jürg worked in the same team and Jürg occasionally produced circuit boards for various electronics projects in his spare time. So it happened that Bojan asked Jürg to etch a small PCB for him and two weeks later he got his hands on the first version of what we now call the intertooth.

The Excitement

Jürg was very enthusiastic about the solution and also wanted a, at that time still nameless, intertooth. The functionality of this version was still reduced to the absolute minimum, only RJ45 console ports were supported, the battery could not be charged via the device itself and there was no case yet. So the two of them sat down and thought about what could be improved on the initial version and what additional features would be useful. The first thing to do was to find a case - the device should survive as long as possible in regular use. At this time we also talked to several colleagues about the project and found out that there was a lot of interest and that some of them would also like to have an intertooth.

The First intertooth

Motivated by the numerous positive feedbacks and the great interest, we set out to develop an improved version of the device. The new version had a housing, an integrated battery that can also be charged directly, a D-SUB connector so that console ports of devices that do not have an RJ45 connector could also be connected.

At the same time, the first simple website was created, on which we presented the intertooth and made it available to interested parties.

Further Improvements

Based on various feedbacks and own experiences in using the intertooth, possible optimizations were identified, which were incorporated into the development of the second version. Thus, the range of functions grew considerably - USB console ports are now also supported, the previously integrated RJ45 cable was replaced by a jack, the LEDs were replaced by SMD LEDs with light pipes, and the previously green power LED was replaced by an RGB LED.

Market Readiness

Demand among colleagues and beyond continued, and we were already able to sell a few intertooths. So we set ourselves the goal of officially launching the intertooth on the market and also distributing it beyond the country's borders. This led us to found Two Wave Technologies GmbH and find out what regulatory requirements had to be met in terms of compliance with applicable guidelines. This was followed by a phase in which we had to deal with a lot of paperwork. On the one hand, for the establishment of the GmbH, and on the other hand, for the FCC and CE certification of the intertooth. In addition to the new conformity logos on the housing, the lettering on the front of the device was also revised and no longer stuck on, but laser engraved. This resulted in the first officially available version of the intertooth.

All intertooths were and still are handmade by us. To further optimize this process, we improved the reflow oven used for this purpose and created hardware and software to efficiently test the devices during and after assembly.

Chip Shortage

Now we had a company, the necessary certifications, a website with an online store, a relatively efficient manufacturing process, and the motivation we needed to move forward with the project. However, we were also challenged by the chip shortage. Several essential components, such as the microcontroller used and the Bluetooth module, suddenly had a delivery time of several months, in some cases even more than a year. In addition, the manufacturer of the Bluetooth module we used stopped production of this model completely. Due to these developments, we were forced to make various changes to the intertooth, evaluate a new Bluetooth module, and switch to a different microcontroller package.

State Today

The chip crisis is history (for the moment at least) and the required components are mostly available again with the usual delivery times. And we continue to work on improving the intertooth. For example, we have recently extended the compatibility with additional USB consoles, which now supports a large number of additional devices. Find out which devices are supported.